Thermal Imaging Inspections in Austin TX Roof, Electrical, Solar and more

Thermal Vision delivers commercial thermal imaginroofs, electrical systems, solar assets, and building envelopes across Centr

Thermal Vision delivers commercial thermal imaginroofs, electrical systems, solar assets, and building envelopes across Centr

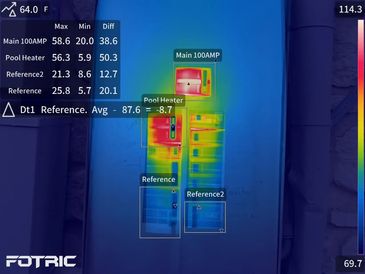

Infrared thermographic surveys are conducted on accessible, energized commercial electrical equipment to evaluate surface temperature distributions under operating load. Observed thermal differentials may be indicative of increased electrical resistance, connection degradation, load imbalance, or component wear. Inspections are performe

Infrared thermographic surveys are conducted on accessible, energized commercial electrical equipment to evaluate surface temperature distributions under operating load. Observed thermal differentials may be indicative of increased electrical resistance, connection degradation, load imbalance, or component wear. Inspections are performed in alignment with recognized industry guidance, including NFPA 70B, and are intended to support reliability focused maintenance strategies and condition monitoring programs.

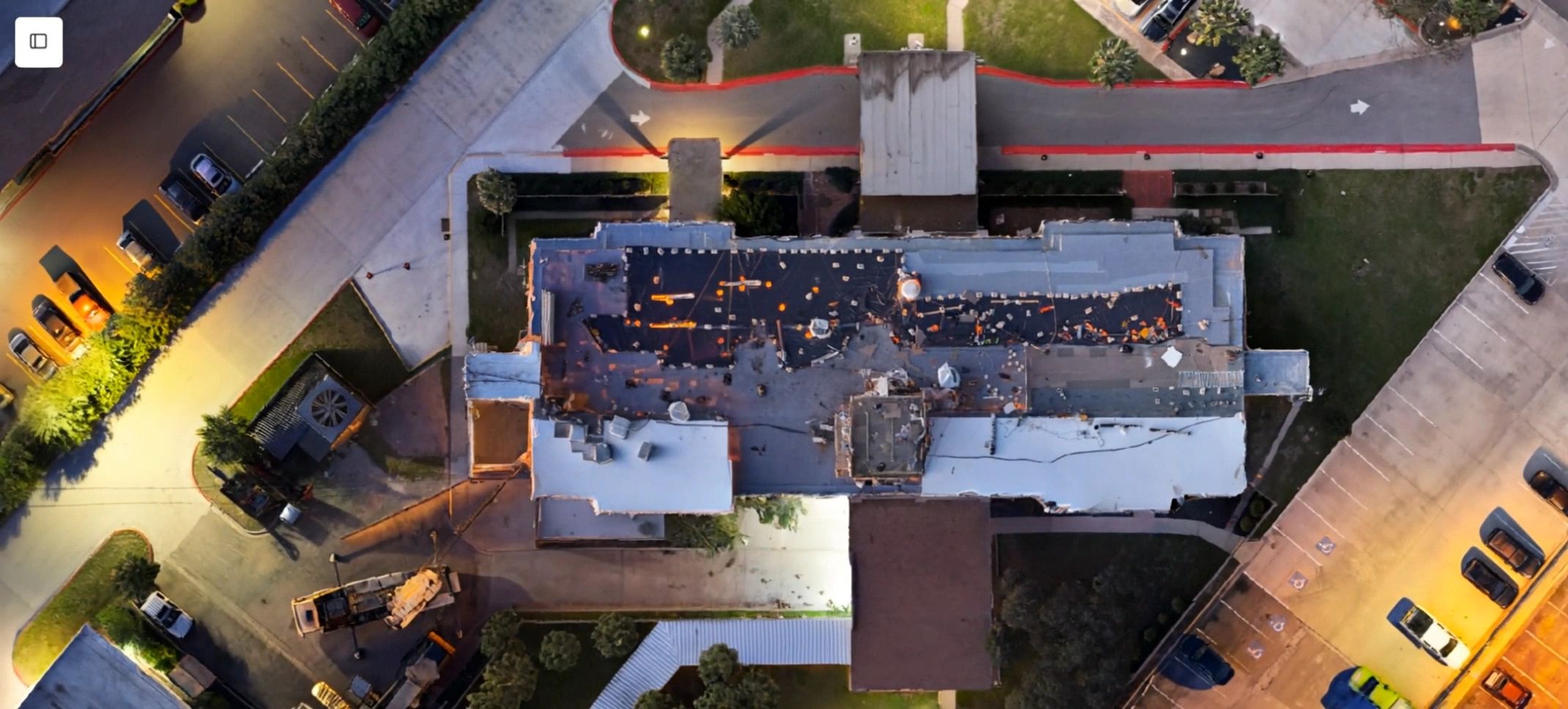

Roof assessments utilize infrared thermography to examine expansive roof assemblies in a non invasive manner. Under appropriate environmental conditions, thermal response variations may be associated with moisture retention, insulation performance anomalies, or heat transfer inconsistencies within the roofing system. Documented findings

Roof assessments utilize infrared thermography to examine expansive roof assemblies in a non invasive manner. Under appropriate environmental conditions, thermal response variations may be associated with moisture retention, insulation performance anomalies, or heat transfer inconsistencies within the roofing system. Documented findings are used to inform focused follow up evaluation, maintenance prioritization, and long term asset planning.

Building envelope evaluations employ thermal imaging to analyze heat transfer behavior across walls, roof systems, fenestrations, and structural transitions. Spatial temperature variations may suggest air exchange pathways, insulation discontinuities, or thermal bridging effects that influence occupant comfort and energy consumption.

Building envelope evaluations employ thermal imaging to analyze heat transfer behavior across walls, roof systems, fenestrations, and structural transitions. Spatial temperature variations may suggest air exchange pathways, insulation discontinuities, or thermal bridging effects that influence occupant comfort and energy consumption. These assessments support data driven decision making related to envelope improvements and efficiency planning.

A trailblazer in thermal imaging and electrical inspections, David Gierke is the founder and driving force behind Thermal Vision, LLC in Austin, TX. — a company not just serving clients, but setting a new heatwave of standards in thermography. Level 2 certified, NFPA-ready, and fueled by a constant push for excellence, David doesn’t just scan rooftops and electrical panels — he scans horizons.

From championing innovative partnerships (like sending FLIR tech to student racing teams) to dreaming up training courses and high-impact sales strategies, David’s got both the engineer’s eye and the entrepreneur’s heart. He’s laser-focused on growth, sharp in strategy, and unstoppable in execution.

On top of that, he’s a proud supporter of rising talent (like Emi, the future aerospace engineer and certified thermographer), an outreach machine, and a master of turning sparks of ideas into full-blown thermal storms.

If it’s about energy, heat, precision, or impact — you’ll find David Gierke at the center, making it happen.

In the world of thermography, resolution is everything. A blurry image can hide a critical electrical fault or a subtle moisture path. That is why Thermal Vision refuses to rely on standard consumer-grade tools. We utilize Fotric industrial thermal imaging systems—the same technology trusted in aerospace research and manufacturing—to deliver Level 3 Certified accuracy. Our cameras offer higher thermal sensitivity and pixel density, ensuring that the data we provide is not just a pretty picture,

We stay in constant communication with our customers until the job is done. To get a free quote, or if you have questions or special requests, just drop us a line.

Open today | 09:00 am – 05:00 pm |

Copyright © 2026 Thermal Vision - All Rights Reserved.